-

Neodymium Magnets

-

Rare Earth Magnets

-

Permanent Magnets

-

Block Neo Magnets

-

Ring Neo Magnets

-

Disc Neo Magnets

-

Cylinder Neo Magnets

-

Arc /Segment Neo magnets

-

Cube Neo Magnets

-

Countersunk NdFeb Magnets

-

Ball Magnets

-

Pot Magnets

-

Magnetic assembly /Couplings

-

Ferrite Magnets

-

AlNiCo Magnets

-

Smco Magnets

-

Rubber/Flexible Magnets

-

Mask

-

Cammy-GermanyProducts and packing is perfect, and our QC is satisfied with them .Your professional suggestion gave us one good design idea .Thanks for your team.

Cammy-GermanyProducts and packing is perfect, and our QC is satisfied with them .Your professional suggestion gave us one good design idea .Thanks for your team. -

Aida-UKYou always provide good service for each details of products.It help us save much of time and energy .Hope we could have more cooperation later .

Aida-UKYou always provide good service for each details of products.It help us save much of time and energy .Hope we could have more cooperation later . -

Sim-USAI have been in purchasing position for many years ,we like to work with your team ,as professional products knowledge,and STRICT QC process .

Sim-USAI have been in purchasing position for many years ,we like to work with your team ,as professional products knowledge,and STRICT QC process . -

Lee -KoreaThanks for your professional suggestion on magnets project.And always nice to work together with you .

Lee -KoreaThanks for your professional suggestion on magnets project.And always nice to work together with you . -

Brete -AustraliaThe products in good packing status,and it works well in our application.Thanks for your effort.

Brete -AustraliaThe products in good packing status,and it works well in our application.Thanks for your effort. -

Garu -SwitzerlandGood Purchasing impression from your company .Professional Products supports deep us .

Garu -SwitzerlandGood Purchasing impression from your company .Professional Products supports deep us .

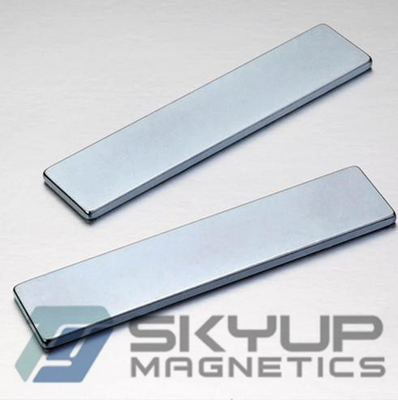

Neodymium Magnet with Manufacturer Of Epoxy Coating N40H Block , Neodymium Magnet Manufacturer

| Place of Origin | China |

|---|---|

| Brand Name | Skyup |

| Certification | ISO9001/TS 16949 |

| Model Number | 35H-50H |

| Minimum Order Quantity | No minimum order quantity |

| Price | USD0.01-0.1/PCS |

| Packaging Details | In cartons, wooden pallet or Box |

| Delivery Time | 15-20Days |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram,Paypal |

| Supply Ability | 15000Tons per year |

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Materials | NdFeB Magnets | Plating | NiCuNi,Zn.Epoxy |

|---|---|---|---|

| Application | Magnets Used In Linear Motor | Capacity | 15000Tons Per Year |

| Certification | ISO/TS 16949,ROHS | Shape | Block,Rectangular,Cube,Block, Cylinder, Disc, Arc, Ring |

Key word: Permanent magnet, Block magnet, NdFeB Magnet, Nd Magnet, Neo Magnet

Material: N52, 38M, 50M, 38H, 38SH, 48SH, 30UH, 45UH, 30EH, 42EH and AH grade etc

Application: Industrial Motor, Linear Motor, Compressor Motor, Wind turbine, Rail Transit Traction Motor etc.

Description

Permanent Nd Magnet in Rectangular Block shape, it is very popular used in industrial Motor, Compressor, Wind turbine applications.

Why choose us?

1) More than 10years experience in NdFeB manufacturing and Marketing

2) Strategic partner of several world top 500 Enterprise, operating well under TS16949

3) Samples and trial orders are welcome

4) Competitive Price & Short Lead Time, cause it is directly from real producer/Manufacturer.

5) Professional suggestion or advice is available when you have doubts in design.

| Grade | Br | HcB | Hcj | (BH )max | Max Working Temperature | ||||||||

| KGs | T | KOe | KA/m | KOe | KA/m | MGOe | KJ/m 3 | L/D=0.7 | |||||

| Max | Min | Max | Min | Min | Min | Min | Min | Max | Min | Max | Min | ℃ | |

| N33 | 11.8 | 11.3 | 1.18 | 1.13 | ≥10.5 | ≥836 | ≥12 | ≥955 | 34 | 31 | 271 | 247 | ≤80 |

| N35 | 12.3 | 11.8 | 1.23 | 1.18 | ≥10.9 | ≥866 | ≥12 | ≥955 | 36 | 33 | 287 | 263 | ≤80 |

| N38 | 12.6 | 12.3 | 1.26 | 1.23 | ≥11.3 | ≥899 | ≥12 | ≥955 | 39 | 36 | 311 | 287 | ≤80 |

| N40 | 12.9 | 12.6 | 1.29 | 1.26 | ≥11.4 | ≥90 | ≥12 | ≥955 | 41 | 38 | 327 | 302 | ≤80 |

| N42 | 13.3 | 12.9 | 1.33 | 1.29 | ≥11.5 | ≥915 | ≥12 | ≥955 | 43 | 40 | 342 | 318 | ≤80 |

| N45 | 13.7 | 13.3 | 1.37 | 1.33 | ≥11.0 | ≥876 | ≥12 | ≥955 | 46 | 43 | 366 | 342 | ≤80 |

| N48 | 14.1 | 13.7 | 1.41 | 1.37 | ≥10.5 | ≥836 | ≥11 | ≥876 | 49 | 45 | 390 | 358 | ≤80 |

| N50 | 14.5 | 14.0 | 1.45 | 1.40 | ≥10.5 | ≥836 | ≥11 | ≥876 | 51 | 47 | 406 | 374 | ≤60 |

| N52 | 14.8 | 14.3 | 1.48 | 1.43 | ≥10.5 | ≥836 | ≥11 | ≥876 | 53 | 49 | 422 | 390 | ≤60 |

| 30M | 11.3 | 10.8 | 1.13 | 1.08 | ≥10 | ≥796 | ≥14 | ≥1114 | 31 | 28 | 247 | 223 | ≤100 |

| 33M | 11.8 | 11.3 | 1.18 | 1.13 | ≥10.5 | ≥836 | ≥14 | ≥1114 | 34 | 31 | 271 | 247 | ≤100 |

| 35M | 12.3 | 11.8 | 1.23 | 1.18 | ≥10.9 | ≥868 | ≥14 | ≥1114 | 36 | 34 | 287 | 271 | ≤100 |

| 38M | 12.6 | 12.3 | 1.26 | 1.23 | ≥11.3 | ≥899 | ≥14 | ≥1114 | 39 | 36 | 311 | 287 | ≤100 |

| 40M | 12.9 | 12.6 | 1.29 | 1.26 | ≥11.6 | ≥923 | ≥14 | ≥1114 | 41 | 38 | 327 | 302 | ≤100 |

| 42M | 13.3 | 12.9 | 1.33 | 1.29 | ≥12 | ≥955 | ≥14 | ≥1114 | 43 | 40 | 342 | 318 | ≤100 |

| 45M | 13.7 | 13.3 | 1.37 | 1.33 | ≥12.5 | ≥995 | ≥14 | ≥1114 | 46 | 43 | 366 | 342 | ≤100 |

| 48M | 14.1 | 13.7 | 1.41 | 1.37 | ≥12.9 | ≥1027 | ≥14 | ≥1114 | 49 | 45 | 390 | 358 | ≤100 |

| 50M | 14.5 | 14.0 | 1.45 | 1.40 | ≥13 | ≥1033 | ≥14 | ≥1114 | 51 | 47 | 406 | 374 | ≤100 |

| 30H | 11.3 | 10.8 | 1.13 | 1.08 | ≥10 | ≥796 | ≥17 | ≥1353 | 31 | 28 | 247 | 223 | ≤120 |

| 33H | 11.8 | 11.3 | 1.18 | 1.13 | ≥10.5 | ≥836 | ≥17 | ≥1353 | 34 | 31 | 271 | 247 | ≤120 |

| 35H | 12.3 | 11.8 | 1.23 | 1.18 | ≥10.9 | ≥868 | ≥17 | ≥1353 | 36 | 33 | 287 | 263 | ≤120 |

| 38H | 12.6 | 12.3 | 1.26 | 1.23 | ≥11.3 | ≥899 | ≥17 | ≥1353 | 39 | 36 | 311 | 287 | ≤120 |

| 40H | 12.9 | 12.6 | 1.29 | 1.26 | ≥11.6 | ≥923 | ≥17 | ≥1353 | 41 | 38 | 327 | 302 | ≤120 |

| 42H | 13.3 | 12.9 | 1.33 | 1.29 | ≥12 | ≥955 | ≥17 | ≥1353 | 43 | 40 | 342 | 318 | ≤120 |

| 45H | 13.7 | 13.3 | 1.37 | 1.33 | ≥12.3 | ≥979 | ≥17 | ≥1353 | 46 | 43 | 366 | 342 | ≤120 |

| Grade | Br | HcB | Hcj | (BH )max | Max Working Temperature | ||||||||

| KGs | T | KOe | KA/m | KOe | KA/m | MGOe | KJ/m 3 | L/D=0.7 | |||||

| Max | Min | Max | Min | Min | Min | Min | Min | Max | Min | Max | Min | ℃ | |

| 48H | 14.1 | 13.7 | 1.41 | 1.37 | ≥12.5 | ≥995 | ≥17 | ≥1353 | 49 | 46 | 390 | 366 | ≤120 |

| 30SH | 11.4 | 10.8 | 1.14 | 1.08 | ≥10.1 | ≥804 | ≥20 | ≥1592 | 31 | 28 | 247 | 223 | ≤150 |

| 33SH | 11.8 | 11.4 | 1.18 | 1.14 | ≥10.6 | ≥844 | ≥20 | ≥1592 | 34 | 31 | 271 | 247 | ≤150 |

| 35SH | 12.3 | 11.8 | 1.23 | 1.18 | ≥11.0 | ≥876 | ≥20 | ≥1592 | 36 | 33 | 287 | 263 | ≤150 |

| 38SH | 12.6 | 12.3 | 1.26 | 1.23 | ≥11.4 | ≥907 | ≥20 | ≥1592 | 39 | 36 | 311 | 287 | ≤150 |

| 40SH | 12.9 | 12.6 | 1.29 | 1.26 | ≥11.6 | ≥939 | ≥20 | ≥1592 | 41 | 38 | 326 | 302 | ≤150 |

| 42SH | 13.3 | 12.9 | 1.33 | 1.29 | ≥12.4 | ≥987 | ≥20 | ≥1592 | 43 | 40 | 342 | 318 | ≤150 |

| 45SH | 13.7 | 13.2 | 1.37 | 1.32 | ≥12.6 | ≥1003 | ≥20 | ≥1592 | 46 | 42 | 366 | 334 | ≤150 |

| 28UH | 10.8 | 10.4 | 1.08 | 1.04 | ≥9.6 | ≥764 | ≥25 | ≥1989 | 29 | 26 | 231 | 207 | ≤180 |

| 30UH | 11.4 | 10.8 | 1.14 | 1.08 | ≥10.1 | ≥804 | ≥25 | ≥1989 | 31 | 28 | 247 | 223 | ≤180 |

| 33UH | 11.8 | 11.4 | 1.18 | 1.14 | ≥10.7 | ≥852 | ≥25 | ≥1989 | 34 | 31 | 271 | 247 | ≤180 |

| 35UH | 12.3 | 11.8 | 1.23 | 1.18 | ≥10.8 | ≥860 | ≥25 | ≥1989 | 36 | 33 | 287 | 263 | ≤180 |

| 38UH | 12.6 | 12.3 | 1.26 | 1.23 | ≥11.3 | ≥899 | ≥25 | ≥1989 | 39 | 36 | 311 | 287 | ≤180 |

| 40UH | 12.9 | 12.5 | 1.29 | 1.25 | ≥11.3 | ≥899 | ≥25 | ≥1989 | 41 | 38 | 326 | 302 | ≤180 |

| 42UH | 13.3 | 12.8 | 1.33 | 1.28 | ≥11.6 | ≥923 | ≥25 | ≥1989 | 43 | 40 | 342 | 318 | ≤180 |

| 28EH | 10.8 | 10.4 | 1.08 | 1.04 | ≥9.8 | ≥780 | ≥30 | ≥2388 | 29 | 26 | 231 | 207 | ≤200 |

| 30EH | 11.4 | 10.8 | 1.14 | 1.08 | ≥10.1 | ≥804 | ≥30 | ≥2388 | 31 | 28 | 247 | 223 | ≤200 |

| 33EH | 11.8 | 11.4 | 1.18 | 1.14 | ≥10.3 | ≥820 | ≥30 | ≥2388 | 34 | 31 | 271 | 247 | ≤200 |

| 35EH | 12.3 | 11.7 | 1.23 | 1.17 | ≥10.5 | ≥836 | ≥30 | ≥2388 | 36 | 33 | 287 | 263 | ≤220 |

| 38EH | 12.6 | 12.2 | 1.26 | 1.22 | ≥11.3 | ≥899 | ≥30 | ≥2388 | 39 | 35 | 311 | 278 | ≤220 |

| 28AH | 10.9 | 10.4 | 1.09 | 1.04 | ≥9.8 | ≥780 | ≥35 | ≥2785 | 29 | 33 | 231 | 207 | ≤230 |

| 30AH | 11.3 | 10.8 | 1.13 | 1.08 | ≥10.1 | ≥804 | ≥35 | ≥2785 | 31 | 26 | 247 | 223 | ≤230 |

| 33AH | 11.8 | 11.3 | 1.18 | 1.13 | ≥10.3 | ≥820 | ≥33 | ≥2625 | 34 | 28 | 271 | 247 | ≤230 |

| 35AH | 12.3 | 11.7 | 1.23 | 1.17 | ≥10.5 | ≥860 | ≥33 | ≥2625 | 36 | 33 | 287 | 263 | ≤230 |

Product Information:

|

Product name |

Permanent, Nd Rectangular/Block magnet, Neo Rectangular/Block magnet, Rare earth Rectangular/Block magnet | |

| Material | Neodymium iron boron, Neo Magnet, Nd Magnet, Rare earth Magnet | |

|

Grade & working Temperature |

Grade | Max Operating Temperatures |

| N35-N54 | 80°C (176°F) | |

| 35M-52M | 100°C (212°F) | |

| 35H-50H | 120°C (248°F) | |

| 33SH-48SH | 150°C (302°F) | |

| 28UH-45UH | 180°C (356°F) | |

| 28EH-42EH | 200°C (392°F) | |

| 28AH-40AH | 230°C (446°F) | |

| Shape | Block or Rectangular or Cuboid, Disc, Ring, Cylinder, Arc and Irregular shape are also available | |

| Coating | Ni, Ni-Cu-Ni, Electroless Nickel, Zinc, Colored Zinc, Epoxy, Passivation, Phosphated, Everlube, Au, Ag, Sn etc. | |

|

Magnetized direction |

Thickness Magnetized, but Axially, Diametrical, Multipoles and Radial magnetization are also available, Customized magnetization is welcome. | |

| Application | Servo motor,Brushless motor, Linear Motor, Automotive Motor, HEV& EV motor, Robot Driving Motor, Inverter Compressor Motor , Rail Transit Traction Motor, Consumer Electronics, Wind turbine, Energy-saving Elevator, Loudspeaker, Magnetic switch, VCM, MRI, Magnetic separator, sensor etc. | |

| Certificate | ISO/TS 16949, ISO9001, ISO14001, RoHS, REACH | |

| Packing | Standard sea or air packing, such as carton, wooden box, pallet etc. | |

| Lead time | 7-10 days for samples, 15-25 days for mass production. | |

| Transportation | All shipping methods are available: courier (TNT, DHL, FedEx, UPS), air or sea. Shipper or freight forwarder can be appointed by either purchaser |

|

1. Production flow of Permanent NdFeB Magnet:

NdFeB Production Process

Raw Materials Prepare —Melting –HD–Jet Milling–Mould /Pressing–Sintering–Magnet Performance Inspection–Machining–Plating –Final Inspection –Magnetizing–Packing–Delivery

![]()

2.Magnetic Property Distribution Chart of Permanent NdFeB Magnet

Neodymium-iron-boron magnet is one kind of the permanent magnets.

Material Grade of NdFeB magnets:

Magnet N-( N35, N38, N40, N42, N45, N48, N50,N52),

Magnet M-(35M, 38M, 40M, 42M, 45M, 48M,50M),

Magnet H-(35H, 38H, 40H, 42H, 45H,48H),

Magnet SH-(30SH, 33SH, 35SH, 38SH, 40SH, 42SH,45SH),

Magnet UH-( 28UH, 30UH, 33UH, 35UH, 38UH,40UH,42UH),

Magnet EH-(28EH, 30EH, 30EH, 33EH, 35EH,38EH,40EH)

Magnet AH-(30AH, 33AH, 35AH, 38AH)

3. Available coating of Permanent NdFeB Magnet:

Ni, NiCuNi, Electroless Nickel, Zinc, Colored Zinc, Epoxy, Passivation, Phosphated, Everlube, Au, Sn etc.

| Available Coatings Of Sintered NdFeB Magnets | ||||||

| Surface | Coating | Thickness (Microns) of coating | Color | Resistance | Salt spray Test Standard (hours) | PCT Standard (hours) |

| Nickel | Ni+Ni | 10--20um | Bright Silver | Excellent against Humidity | >24-72 | >24-72 |

| Ni+Cu+Ni | ||||||

| Black Nickel | Ni+Cu+Ni | 10-20um | Bright black | Excellent Against Humidity & Salt Spray | >48-96 | >48 |

| Cr3+Zinc | ZN | 5--8um | Bright Blue | Good Against Salt Spray | >16-48 | |

| Color-Zn | ShiningColor | Excellent Against Salt Spray | >36-72 | |||

| Epoxy | Epoxy | 10-20um | Black,Grey | Excellent Against Humidity & Salt Spray | >48 | |

| Ni+Cu+Epoxy | 10-30um | >72-108 | ||||

| Zn+Epoxy | 15-25um | >72-108 | ||||

| Passivation | _ | 1--3um | Dark Grey | Temporary Protection | _ | _ |

| Phosphated | _ | 1--3um | Dark Grey | Temporary Protection | _ | _ |

| Sn | Ni+Cu+Ni+Sn | 10-25um | Silver | Superior Against Humidity | >36-72 | >48 |

| Au | Ni+Cu+Ni+Au | 10-15um | Gold | Superior Sgainst Humidity | >12 | >48 |

| Ag | Ni+Cu+Ni+Ag | 10-15um | Silver | Superior Against Humidity | >12 | >48 |

4. Magnetized Direction of NdFeB magnet:

Thickness, Axially, Diametrical, Multipoles and Radial magnetization are available, Customized

magnetization is welcome.

![]()

5.Applications of Permanent NdFeB Magnet:

NdFeB Magnet are widely used in Servo motor, Brushless motor, Linear Motor, Automotive Motor, HEV& EV motor, Robot Driving Motor, Inverter Compressor Motor , Traction Motor, wind turbine, Energy-saving Elevator, Loudspeaker, Magnetic switch, VCM, MRI, Magnetic separator, sensor etc.

6.Packing of Permanent NdFeB Magnet:

Standard sea or air packing, such as carton, wooden box and pallet etc.

![]()

7.Engineering and Research center of Permanent NdFeB Magnet:

Our engineering center equiped with advanced analytical methods and full set of sophisticated test apparatuses, it not only assured the top quality of product, but also the foundation of our research and technic improving. The main test apparatuses are as follow:

6S Total Quality Management(TQC), with good quality and magnetic solutions, flexible service to satisfy our clients.

With the implementation of TQM, from raw materials to finished products to package and delivery, We carry out strict inspection and effective quality planning, to ensure magnets' quality. We always fo our best to meet our customers' request.

![]()

If you have any question about us, welcome to contact us anytime.

Contact: Coco

Email: coco@cnmagnets.com

Skype: coco.magnet@hotmail.com

Mobile:0086-15757403848 (Whatapp/Wechat )

Tel:0086-574-26866228

Website: www.cnmagnets.com