-

Neodymium Magnets

-

Rare Earth Magnets

-

Permanent Magnets

-

Block Neo Magnets

-

Ring Neo Magnets

-

Disc Neo Magnets

-

Cylinder Neo Magnets

-

Arc /Segment Neo magnets

-

Cube Neo Magnets

-

Countersunk NdFeb Magnets

-

Ball Magnets

-

Pot Magnets

-

Magnetic assembly /Couplings

-

Ferrite Magnets

-

AlNiCo Magnets

-

Smco Magnets

-

Rubber/Flexible Magnets

-

Cammy-GermanyProducts and packing is perfect, and our QC is satisfied with them .Your professional suggestion gave us one good design idea .Thanks for your team.

Cammy-GermanyProducts and packing is perfect, and our QC is satisfied with them .Your professional suggestion gave us one good design idea .Thanks for your team. -

Aida-UKYou always provide good service for each details of products.It help us save much of time and energy .Hope we could have more cooperation later .

Aida-UKYou always provide good service for each details of products.It help us save much of time and energy .Hope we could have more cooperation later . -

Sim-USAI have been in purchasing position for many years ,we like to work with your team ,as professional products knowledge,and STRICT QC process .

Sim-USAI have been in purchasing position for many years ,we like to work with your team ,as professional products knowledge,and STRICT QC process . -

Lee -KoreaThanks for your professional suggestion on magnets project.And always nice to work together with you .

Lee -KoreaThanks for your professional suggestion on magnets project.And always nice to work together with you . -

Brete -AustraliaThe products in good packing status,and it works well in our application.Thanks for your effort.

Brete -AustraliaThe products in good packing status,and it works well in our application.Thanks for your effort. -

Garu -SwitzerlandGood Purchasing impression from your company .Professional Products supports deep us .

Garu -SwitzerlandGood Purchasing impression from your company .Professional Products supports deep us .

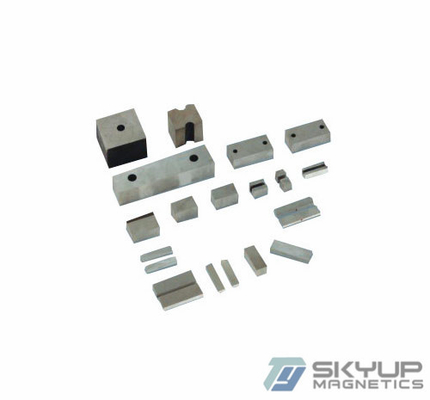

High performance AlNiCo magnets Magnets used in motors, generators,Pumps

| Place of Origin | China |

|---|---|

| Brand Name | Skyup |

| Certification | ISO9001,TS16949,SGS |

| Model Number | AlNiCo1-9 |

| Minimum Order Quantity | 1pcs |

| Price | 0.01-0.1USD/Pcs |

| Packaging Details | In cartons,Pallets,woode box etc |

| Delivery Time | 10-20Days |

| Payment Terms | T/T,L/C,D/P,D/A,Western Union,Money Gram |

| Supply Ability | 2500tons Per year |

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Materials | AlNiCo Magnet | Surface Finish | As Customer Requirement |

|---|---|---|---|

| Capacity | 15000Tons Per Year | Application | Point Of Sale, Window Dressing, Door / Cupboard And Gate Clamps, False Ceiling Clamps, Signs And Banners, Torque Limited Seals, Jigs And Fixtures, Lighting Holders, Marketing And Exhibition Displays, Retrieval Magnets, Industrial Fixings, Etc. |

| Manufacturer | Skyup Magnetics | Production Periods | 15-20days |

01. AlNiCo Magnets Introduction

Alnico magnets are made of aluminum, nickel, cobalt, copper, iron and other materials. Based on different processing technology, it can be divided into cast and sintered magnets. We can supply both cast and sintered alnico magnets in a variety shapes including horseshoe, U shape, bar, block, disc, ring, rod and other customized shapes. Compared to other permanent magnets like neodymium iron boron (NdFeB), the main features are excellent resistance to high temperature (up to 550℃) and high residual induction.

Plating:

Usually supplied in un-plated condition

If specially requested by customers, we can plate alnico magnets with NiCuNi. But as it has weak adhesion to plating, NiCuNi plating might flake off if not handled properly.

Cast alnico magnets are mainly applied in automotive parts, instruments, electro-acoustic, electrical, teaching equipments, aviation and military areas. Sintered Alnico magnets are widely used in fields of instrumentation, communications, electronic, magnetic switches, sensors and others.

Given the low coercive force of alnico permanent magnet , in order to avoid irreversible demagnetization or disorder of magnetic flux distribution, alnico magnets shall be strictly kept apart from other magnetic materials in actual application or shipping process, especially neodymium magnet material.

With the principle of quality, credit, price concessions and prompt delivery, we warmly welcome new and old customers to make inquiries.

02. Cast AlNiCo Magnet

We supply Cast Alnico magnets with stronger magnetic performance than Sintered Alnico. And cast Alnico permanent magnets can be customized into different sizes and shapes. No surface treatment is needed on Alnico magnets owing to their strong resistance to corrosion and oxidation in extend environmental condition. If some customers think coated Alnico magnets are better for their application, we can coat Nickel or Zn on Alnico magnets. However, coated Alnico magnets look not as beautiful as coated neodymium magnets due to the different material surface and texture.

The manufacturing process of Cast Alnico magnets mainly includes nine processes. Melting process is special handicraft technology which is not easily controlled. The operators need certain skills and experience to handle it. Material mixing and magnetic heat treatment are key procedures.

The main manufacturing process of Cast Alnico magnets is listed as follows

Raw material → Mixing → Melting → Molding Casting → Heat Treatment → Magnetic Testing → Grinding → Inspection → Finalpermanent magnet

Typical Magnetic Performance for Cast AlNiCo Magnet —USAStandard

![]()

Typical Magnetic Performance for Cast AlNiCo Magnet — Chinese Standard

![]()

03. Sinter AlNiCo Magnet

According to the different manufacturing process, alnico permanent magnet material can be divided into two main series of Cast Alnico magnet and Powder Sintered Alnico magnet.

Powder Sintered Alnico series is divided into isotropic Alnico and thermo magnetic treatment anisotropic Alnico.

Sintered Alnico magnets are slightly weaker than Cast Alnico magnets in magnetic strength, but their sizes and dimensional tolerance are relatively smaller than cast ones.

Sintered Alnico magnets are more often used in micro/small motors, permanent magnet motor, relays and some small instruments.

Sintered Alnico magnets are made from powdered mixture of raw materials that are pressed into a die under tons of pressure. They are then sintered in a hydrogen atmosphere and cooled in an anisotropic or isotropic environment.

The main manufacturing process of Sintered Alnico magnetic materials is listed as following.

Raw material → Mixing → Powder → Pressing → Sintering → Heat Treatment → Magnetic Testing → Grinding → Inspection → Final Alnico magnet

Typical Magnetic Performance for Sintered AlNiCo Magnet — Chinese Standard

![]()

Why choose us?

1) More than 10years experience in NdFeB manufacturing and Marketing

2) Strategic partner of several world top 500 Enterprise, operating well under TS16949

3) Samples and trial orders are welcome

4) Competitive Price & Short Lead Time, cause it is directly from real producer/Manufacturer.

5) Professional suggestion or advice is available when you have doubts in design.

If you have any question about us, welcome to contact us anytime.

Contact: Coco

Email: coco@cnmagnets.com

Skype: coco.magnet@hotmail.com

Mobile:0086-15757403848 (Whatapp/Wechat )

Tel:0086-574-26866228

Website: www.cnmagnets.com