-

Neodymium Magnets

-

Rare Earth Magnets

-

Permanent Magnets

-

Block Neo Magnets

-

Ring Neo Magnets

-

Disc Neo Magnets

-

Cylinder Neo Magnets

-

Arc /Segment Neo magnets

-

Cube Neo Magnets

-

Countersunk NdFeb Magnets

-

Ball Magnets

-

Pot Magnets

-

Magnetic assembly /Couplings

-

Ferrite Magnets

-

AlNiCo Magnets

-

Smco Magnets

-

Rubber/Flexible Magnets

-

Cammy-GermanyProducts and packing is perfect, and our QC is satisfied with them .Your professional suggestion gave us one good design idea .Thanks for your team.

Cammy-GermanyProducts and packing is perfect, and our QC is satisfied with them .Your professional suggestion gave us one good design idea .Thanks for your team. -

Aida-UKYou always provide good service for each details of products.It help us save much of time and energy .Hope we could have more cooperation later .

Aida-UKYou always provide good service for each details of products.It help us save much of time and energy .Hope we could have more cooperation later . -

Sim-USAI have been in purchasing position for many years ,we like to work with your team ,as professional products knowledge,and STRICT QC process .

Sim-USAI have been in purchasing position for many years ,we like to work with your team ,as professional products knowledge,and STRICT QC process . -

Lee -KoreaThanks for your professional suggestion on magnets project.And always nice to work together with you .

Lee -KoreaThanks for your professional suggestion on magnets project.And always nice to work together with you . -

Brete -AustraliaThe products in good packing status,and it works well in our application.Thanks for your effort.

Brete -AustraliaThe products in good packing status,and it works well in our application.Thanks for your effort. -

Garu -SwitzerlandGood Purchasing impression from your company .Professional Products supports deep us .

Garu -SwitzerlandGood Purchasing impression from your company .Professional Products supports deep us .

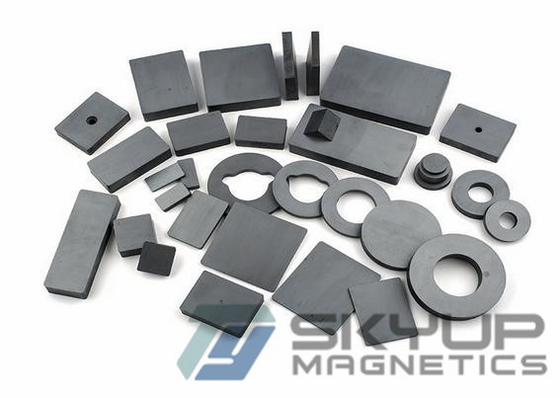

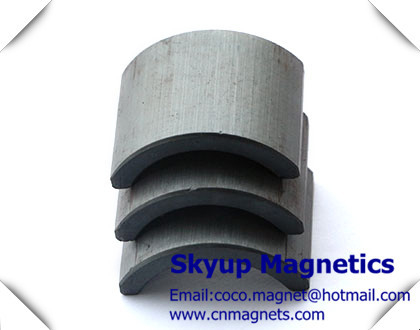

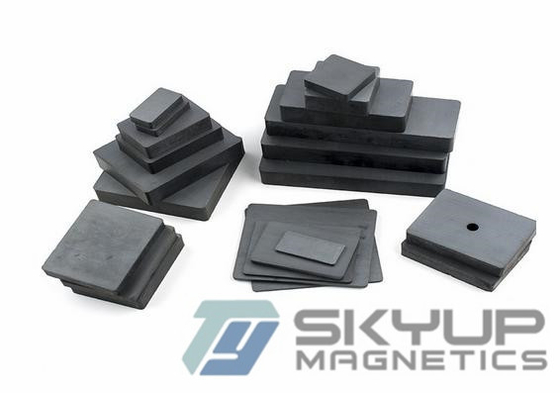

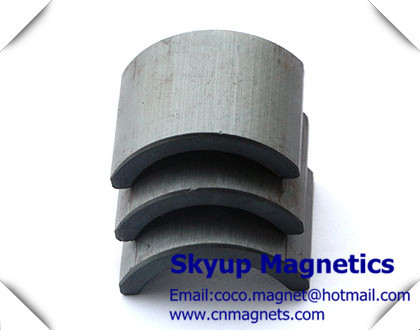

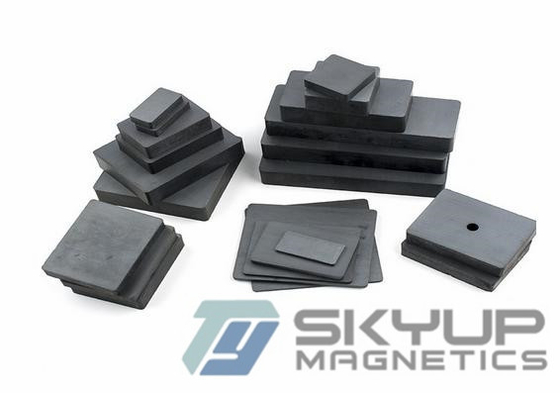

12 Years Experience customized Barium Ferrite block/ring/disc/ arc ceramic magnet

| Place of Origin | China |

|---|---|

| Brand Name | Skyup |

| Certification | ISO9001/TS 16949 |

| Model Number | 35H-50H |

| Minimum Order Quantity | No minimum order quantity |

| Price | USD0.01-0.1/PCS |

| Packaging Details | In cartons, wooden pallet or Box |

| Delivery Time | 15-20Days |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram,Paypal |

| Supply Ability | 15000Tons per year |

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Materials | Rubber/Flexible Magnet | Plating | NiCuNi,Zn.Epoxy |

|---|---|---|---|

| Application | Magnets Used In Linear Motor | Capacity | 15000Tons Per Year |

| Certification | ISO/TS 16949,ROHS | Shape | Block,Rectangular,Cube,Block, Cylinder, Disc, Arc, Ring |

01.Ceramic /Ferrite Magnets Introduction

Ceramic magnet, i.e. ferrite magnet, is a kind of permanent magnet mainly manufactured by raw material of (SrO) SrO or BaO and Fe2O3. Compared with other magnets, ferrite magnet is hard and brittle, and the magnetic energy is relatively low. But it is difficult to demagnetize and go corrosion, the production process is simple and the price is cheap, therefore, in the whole magnet industry the output of ferrite magnet is the highest and they are widely used in industrial production.

Ferrite magnets belong to sintered permanent magnetic materials , are composed of barium or strontium iron body mainly. This kind of magnet has a strong resistance to demagnetization, and owns the advantages of low cost in addition. Ferrite magnets are hard and brittle. They need special machining process in production. It can be divided into anisotropic magnets and isotropic ferrite magnets. The magnetism orientation of anisotropic ferrite magnets is oriented in a certain direction, and can only be magnetized along this direction. While there is no certain orientation of isotropic ferrite magnets, so they can be magnetized along any direction after production. Isotropic ferrite magnet is relatively weaker than anisotropic one. The magnetic energy product range of ferrite magnets is between 1.1 MGOe to 4.0 MGOe. Owing to the low cost and economic effect, ferrite magnet has a very wide application field from the motors, the speakers, the toys to crafts, so it is the most widely used permanent magnet material.

02.Typical Magnetic Performance for Ceramic Magnets

Mostly Used Standard

| Grade | Value(min/typical in our factory) | |||||||

| Br | Hcb(BHC) | Hcj(IHC) | (BH)max | |||||

| MT | KG | KA/m | Koe | KA/m | KOe | Kj/m3 | MGOe | |

| Y10T(=C1) | 200/218 | 2.00/2.18 | 125/145 | 1.57/1.82 | 210/250 | 2.64/3.14 | 6.5/8.0 | 0.8/1.0 |

| Y25 | 360/370 | 3.60/3.70 | 135/150 | 1.70/1.88 | 140/170 | 1.76/2.14 | 22.5/25.3 | 2.8/3.2 |

| Y30(=C5) | 380/385 | 3.80/3.85 | 191/210 | 2.40/2.64 | 199/220 | 2.50/2.51 | 26.0/28 | 3.4/3.7 |

| Y30BH | 380/390 | 3.80/3.90 | 223/235 | 2.80/2.95 | 231/245 | 2.90/3.08 | 27.0/30.0 | 3.4/3.7 |

| Y33 | 410/420 | 4.10/4.20 | 220/235 | 2.77/2.95 | 225/240 | 2.83/3.01 | 31.5/33.0 | 4.0/4.2 |

| Y35 | 400/410 | 4.00/4.10 | 175/195 | 2.20/2.45 | 180/200 | 2.26/2.51 | 30.0/32.0 | 3.8/4.0 |

| C8(=C8A) | 385/390 | 3.85/3.90 | 235/255 | 2.95/3.20 | 242/265 | 3.05/3.33 | 27.8/30.0 | 3.5/3.7 |

| C10 | 400/410 | 4.00/4.10 | 288/300 | 3.62/3.77 | 280/287 | 3.51/3.60 | 30.4/31.9 | 3.8/4.0 |

Chinese Standard

![]()

USA Standard

![]()

Europe Standard

OX100=Y10T=C1 OX300=Y30=C5 OX330=Y30BH

The standard from International Electronics Committee(IEC404-8-1)

| Grade | Allowed Value (min/typical) | |||||||

| Br | Hcb(BHC) | Hcj(IHC) | (BH)max | |||||

| MT | KG | KA/m | KOe | KA/m | KOe | Kj/m3 | MGOe | |

| HF8/22 | 200/220 | 2.00/2.20 | 125/140 | 1.57/1.76 | 220/230 | 2.76/2.89 | 6.5/6.8 | 0.8/1.1 |

| HF20/19 | 320/333 | 3.20/3.33 | 170/190 | 2.14/2.39 | 190/200 | 2.39/2.51 | 20.0/21.0 | 2.5/2.7 |

| HF20/28 | 310/325 | 3.10/3.25 | 220/230 | 2.76/2.89 | 280/290 | 3.52/3.64 | 20.0/21.0 | 2.5/2.7 |

| HF22/30 | 350/365 | 3.50/3.65 | 255/265 | 3.20/3.33 | 290/300 | 3.64/3.77 | 22.0/23.5 | 2.8/3.0 |

| HF24/16 | 350/365 | 3.50/3.65 | 155/175 | 1.95/2.20 | 160/180 | 2.01/2.26 | 24.0/25.5 | 3.0/3.2 |

| HF24/23 | 350/365 | 3.50/3.65 | 220/230 | 2.76/2.89 | 230/240 | 2.89/3.01 | 24.0/25.5 | 3.0/3.2 |

| HF24/35 | 360/370 | 3.60/3.70 | 260/270 | 3.27/3.39 | 350/360 | 4.40/4.52 | 24.0/25.5 | 3.0/3.2 |

| HF26/16 | 370/380 | 3.70/3.80 | 155/175 | 1.95/2.20 | 160/180 | 2.01/2.26 | 26.0/27.0 | 3.2/3.4 |

| HF26/18 | 370/380 | 3.70/3.80 | 175/190 | 2.20/2.39 | 180/190 | 2.26/2.39 | 26.0/27.0 | 3.3/3.4 |

| HF26/24 | 370/380 | 3.70/3.80 | 230/240 | 2.89/3.01 | 240/250 | 3.01/3.14 | 26.0/27.0 | 3.3/3.4 |

| HF26/26 | 370/380 | 3.70/3.80 | 230/240 | 2.89/3.01 | 260/270 | 3.27/3.39 | 26.0/27.0 | 3.3/3.4 |

| HF26/30 | 385/395 | 3.85/3.95 | 260/270 | 3.27/3.39 | 300/310 | 3.77/3.89 | 26.0/27.0 | 3.3/3.4 |

| HF28/26 | 385/395 | 3.85/3.95 | 250/265 | 3.14/3.33 | 260/275 | 3.27/3.45 | 28.0/30.0 | 3.5/3.8 |

| HF28/28 | 385/395 | 3.85/3.95 | 260/270 | 3.27/3.39 | 280/290 | 3.50/3.60 | 28.0/30.0 | 3.5/3.8 |

| HF30/26 | 395/405 | 3.95/4.05 | 250/260 | 3.14/3.33 | 260/270 | 3.27/3.39 | 30.0/31.5 | 3.8/3.9 |

| HF32/17 | 410/420 | 4.10/4.20 | 160/180 | 2.01/2.26 | 165/175 | 2.07/2.20 | 32.0/33.0 | 4.0/4.1 |

| HF32/22 | 410/420 | 4.10/4.20 | 215/225 | 2.70/2.83 | 220/230 | 2.76/2.89 | 32.0/33.0 | 4.0/4.1 |

| HF32/25 | 410/420 | 4.10/4.20 | 240/250 | 3.01/3.14 | 250/260 | 3.14/3.27 | 32.0/33.0 | 4.0/4.1 |

03.Ceramic Magnets

Ferrite magnets are permanent magnets , not rare earth magnets, it is mainly made from iron oxide and strontium carbonate by ceramic processing technology, also called ceramic magnets.

Ferrite magnets are brittle, can be manufactured by die pressing and then sintering, can be made into various shapes and sizes. Its normal operating temperature is between -40℃ and 250℃. Ceramic magnets are the most commonly used permanent magnet materials due to their low cost, easy to produce, excellent corrosion and demagnetization resistance properties. It can be produced either isotropic or anisotropic. C3, C5 & C8 magnets are anisotropic. If you need the strongest magnetic materials, we suggest sintered NdFeB magnets like N52.

If you demand such magnets, welcome to send us the details as follows:

Type: Permanent Magnet

Material: Sintered Ferrite

Grade: Y30, Y30BH, Y33 etc

Magnetization Direction

Shape & Size & Tolerance: According to clients’ requirement, can custom special & complex shapes

Application: industrial, motors, speaker, air conditioning systems, crafts, daily life, cow, etc.

Why choose us?

1) More than 10years experience in NdFeB manufacturing and Marketing

2) Strategic partner of several world top 500 Enterprise, operating well under TS16949

3) Samples and trial orders are welcome

4) Competitive Price & Short Lead Time, cause it is directly from real producer/Manufacturer.

5) Professional suggestion or advice is available when you have doubts in design.

If you have any question about us, welcome to contact us anytime.

Contact: Coco

Email: coco@cnmagnets.com

Skype: coco.magnet@hotmail.com

Mobile:0086-15757403848 (Whatapp/Wechat )

Tel:0086-574-26866228

Website: www.cnmagnets.com